Viele Freunde fügen bei der Auswahl von Optik-Kits zum Modifizieren von Motorrädern gerne einige Verzierungen aus Kohlefaser hinzu, aber kennen Sie den Unterschied zwischen den beiden derzeit auf dem Markt erhältlichen Kohlefaserarten?

1. Erfahren Sie mehr über Kohlefasermaterialien

Lassen Sie uns zunächst einige der Eigenschaften von Kohlefasermaterialien verstehen. Kohlefasermaterialien sind Spezialfasern mit einem Kohlenstoffgehalt von über 95 % (hergestellt aus Acryl- und Viskosefasern als Rohstoffe, oxidiert und karbonisiert bei hohen Temperaturen). Sie weisen eine hohe Festigkeit auf. Ein neuartiges Fasermaterial mit geringer Dichte, geringem Gewicht, hoher Temperaturbeständigkeit, Reibungsfestigkeit und Leitfähigkeit. Es ist leichter als Aluminiummetall, aber fester als Stahl und weist Korrosionsbeständigkeit und hohe Festigkeit auf. Daher wird es derzeit häufig in der Luftfahrt, der Militärindustrie, der Schifffahrt, im Sport, im Wassersport, in der Medizin und in der Innen- und Außendekoration von Automobilen usw. eingesetzt.

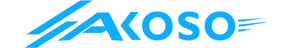

2. Produktionsmethoden und Eigenschaften von nassen Kohlenstofffasern

Die erste Methode ist das Handlaminieren. Nachdem das nicht zuvor in Epoxidharz getränkte Kohlefasergewebe in die gewünschte Form geschnitten wurde, wird zunächst ein Trennmittel auf das Schleifwerkzeug aufgetragen und anschließend auf jede Schicht Kohlefasergewebe eine Schicht Epoxidharz aufgetragen. Das Harz wirkt bis zur Fertigstellung als Bindemittel.

Die zweite Methode ist das Vakuumverfahren. Die Herstellungsmethode unterscheidet sich kaum vom Handlaminierverfahren, allerdings muss Epoxidharz nicht schichtweise in großen Mengen aufgetragen werden. Denn während des Produktionsprozesses werden zunächst die Leitungen und Umleitungsnetze verlegt. Die Leitungen dienen der vollständigen Harzzufuhr, die Umleitungsnetze leiten das Harz, damit es gleichmäßiger auf dem Kohlefasergewebe fließen und sich verteilen kann. Nach dem Absaugen wird überschüssiges Harz abgesaugt, um ein Überlaufen des Klebstoffs zu vermeiden.

Die Mängel des Handlaminierens und des Vakuums sind ebenfalls offensichtlich, d. h., das Produkt weist einen erheblichen Klebstoffüberlauf auf, verformt sich leicht, ist nicht stabil genug, nicht flach genug, vergilbt leicht, verformt sich leicht, ist nicht haltbar, nicht kältebeständig, hat keine dreidimensional strukturierte Oberfläche und eine geringe Oberflächenglätte. Die Genauigkeit ist nicht hoch.

3. Produktionsmethoden und Eigenschaften von trockenen Kohlenstofffasern

Für trockene Kohlefaser wird Prepreg-Gewebe verwendet, das mit Epoxidharz beschichtet ist. Das Prepreg-Gewebe wird zugeschnitten und auf eine Stahlform gelegt. Anschließend wird das gesamte Teil zum Formen in einen Autoklaven gegeben. Für Teile, die eine höhere Präzision erfordern, wird Prepreg-Gewebe auf das Epoxidharz- oder Stahlmodell gelegt, mit einem Vakuumbeutel abgedeckt und in den Autoklaven geschickt. Der Autoklaventransport ist notwendig, da trockene Kohlefaserteile unter bestimmten Temperaturen und Drücken ausgehärtet und geformt werden müssen. Daher ist ein Autoklav erforderlich.

4. Kontrast

Aufgrund des wesentlichen Unterschieds im Produktionsprozess wird Trockenkohlenstoff unter Verwendung von Prepreg-Gewebe unter hoher Temperatur und hohem Druck integral geformt, wodurch ein ausreichend geringes Gewicht und eine hohe Festigkeit erreicht werden. Nasskohlenstoff hingegen wird mit Klebstoffen fixiert und geformt und erfordert mehr Bürsten. Harz ist in der Regel schwerer und die Festigkeit geringer. Die Herstellung von Nasskohlenstofffasern ist wesentlich einfacher als die von Trockenkohlenstofffasern, und auch die Kosten unterscheiden sich stark. Nasskohlenstoff ist im Allgemeinen günstiger als Trockenkohlenstoff.

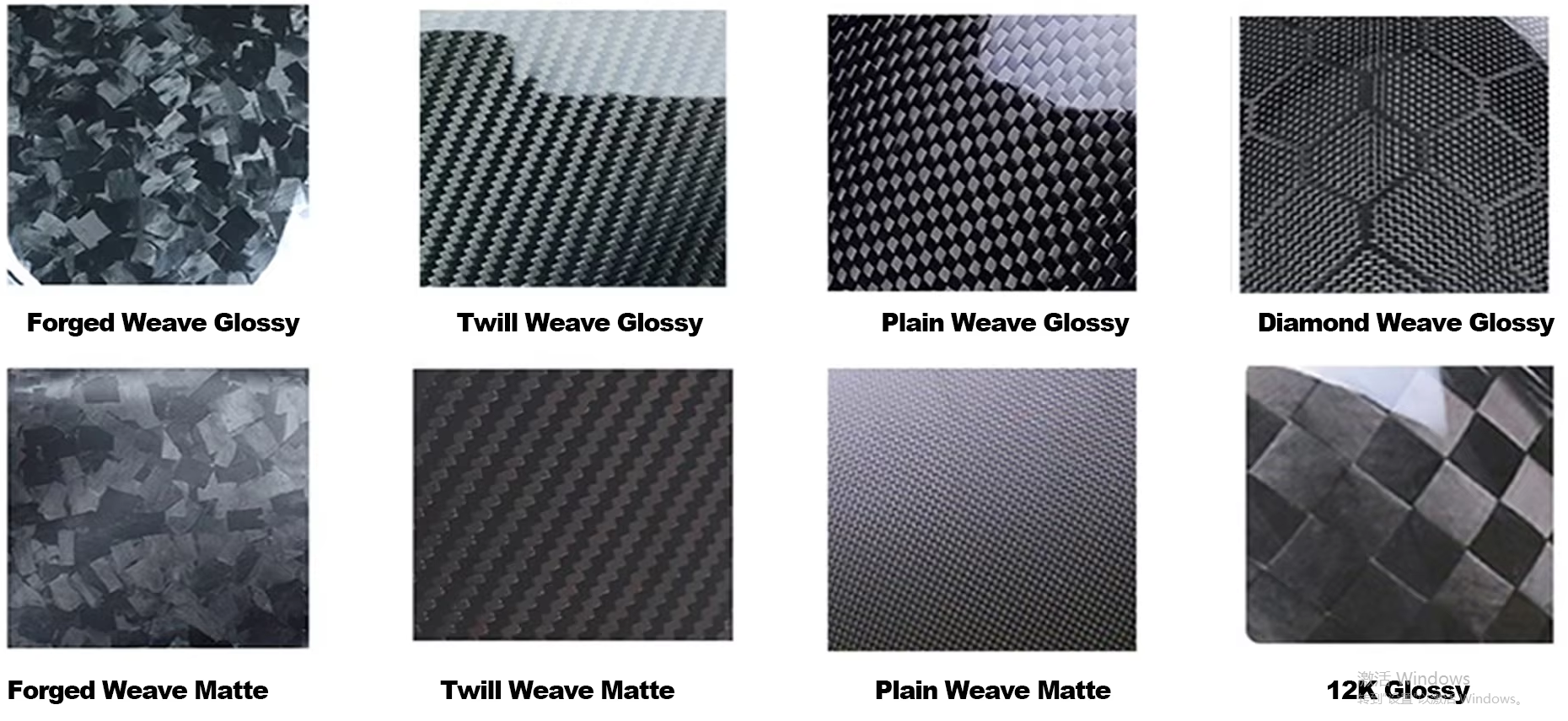

5. Vergleichen Sie Nasskohle- und Trockenkohleprodukte